Supply chain optimization is a critical aspect of business operations, regardless of the industry or size of a company. It can help you reduce shipping errors, lower costs, and eliminate time-consuming processes.

Supply chains can make or break your business, no matter the industry, and it can happen fast. We have all heard the story of how the giant multi-billion retailer Target saw profits tank by almost 90% — all due to supply chain management breakdown and inventory issues in 2016.

Large corporations aren’t the only businesses that experience problems with supply chains. In the wake of the COVID-19 pandemic, nearly 40% of U.S. small businesses faced supply chain delays, according to research.

It’s not just about the money saved — think about the time that has to be reallocated to solve these supply chain breakdowns. Businesses that invest in supply chain optimization upfront can cut costs, save time, and boost profits.

3 steps to optimize your supply chain

Once you’ve decided that it’s time to take a serious look at your supply chain, you must start by first examining what real supply chain optimization looks like.

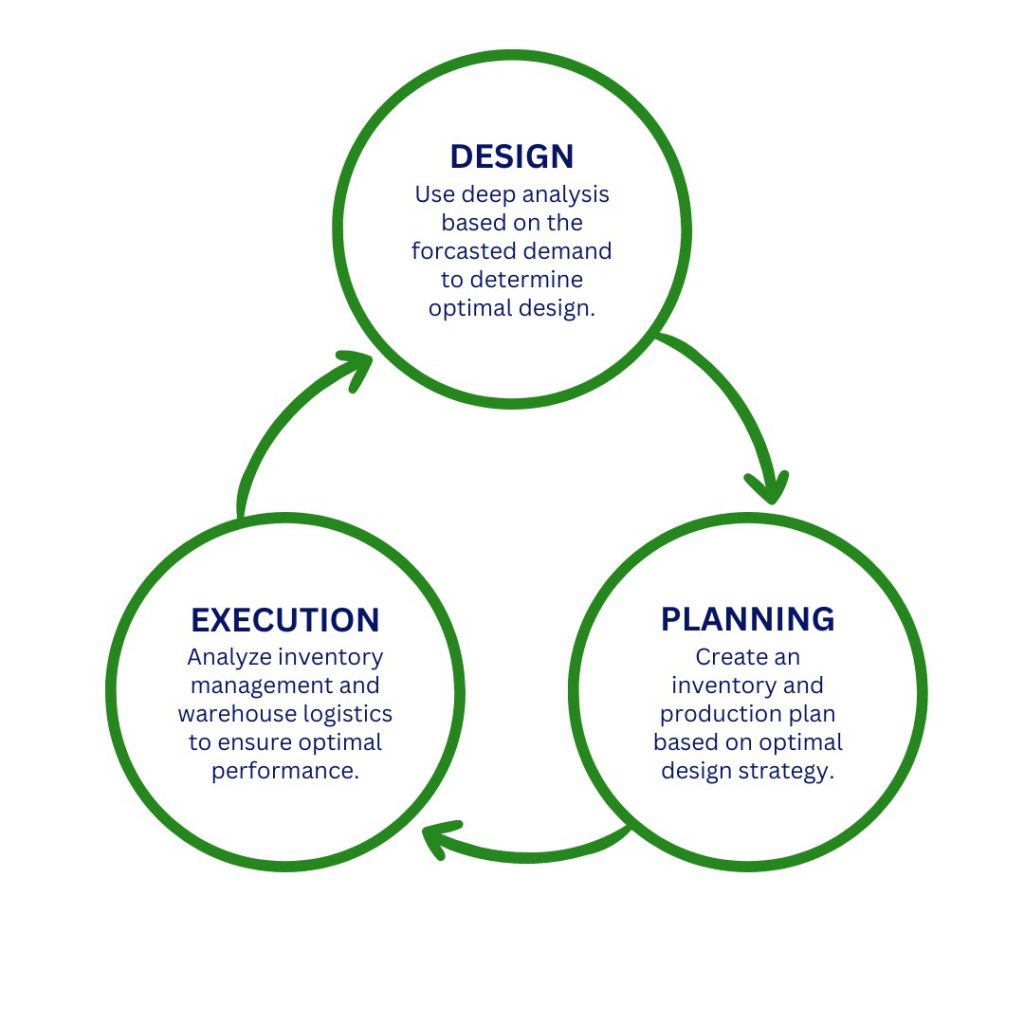

A successful supply chain optimization process includes three main facets:

- Supply chain design — Use deep analysis based on forecasted demand to see if your supply chain is designed optimally, and make necessary changes to achieve the best design possible. This will look different depending on the size of your business as well as the industry.

- Supply chain planning — Create a production and inventory plan based on the optimal design of your supply chain. Additionally, you will coordinate logistics like product/service delivery and communication channels from procurement to customers.

- Supply chain execution – Analyze at your inventory management and warehouse logistics to make sure they are executing to their full potential.

To optimize a supply chain, it is essential to understand the entire process, from the procurement of raw materials, to the assembly, and distribution of finished products or services to the end-user.

Why is supply chain optimization important?

Supply chain optimization determines that the right products will be delivered to the right people at the right time. Without a sustainable and robust supply chain, your business is at risk of over promising and under delivering.

Optimizing the supply chain can improve efficiency, reduce costs, and improve customer satisfaction, ultimately leading to improved overall business performance. When your supply chain is performing at its best, problems are less likely to happen. In addition, when difficulties do come up, it’s far easier to jump into action and know how to quickly fix them.

To achieve the benefits of supply chain optimization, organizations need to invest in the best technology available that will empower them to ship smarter, not harder. This includes investing in advanced analytics and data-driven decision making tools, implementing end-to-end visibility solutions, and finding ways to automate warehouse workflows.

What are the benefits of supply chain optimization?

Optimizing your supply chain brings several benefits, with two main benefits taking center stage: cost reduction and customer satisfaction.

Cost reduction

One of the most compelling benefits of supply chain optimization is cost reduction. When you take the time to improve your supply chain and implement solutions to help you maintain a robust supply chain, it will significantly reduce your costs.

Streamlining processes, reducing inventory levels, and improving transportation efficiency are all ways to cut costs with supply chain optimization. When costs are reduced, organizations remain competitive in their market and increase their profit margins.

Customer satisfaction

Another key advantage of supply chain optimization is improved customer satisfaction. When the speed and reliability of the supply chain is enhanced, organizations can deliver better products to their customers faster and more reliably.

What happens when customers get better service? Increased customer satisfaction, loyalty, and eventually evangelism. When customers are happy, they’re more likely to recommend those services and products to others.

Research shows that 93% of consumers are more likely to stick with the same company (and make repeat purchases) when they’ve had a positive experience. Unfortunately, it works both ways — 33% of American consumers report that after just one bad experience, they consider switching companies. Happy customers come back for more, and that leads to more sales for you.

Supply chain optimization creates a positive chain reaction for your business: With a better supply chain, you’ll experience less risk of processes breaking down, happier customers as a result of more reliable service, and higher profit margins thanks to cost-cutting measures. Successful supply chain optimization is a huge win for your business that will continue to pay dividends for years to come.

5 ways to implement supply chain optimization

The supply chain was once a very manual process. With the advent of technology, however, the ability to optimize and improve efficiencies has accelerated dramatically. Outlined below are five of the best ways to implement supply chain optimization for your business:

1. Reduce lead times

Reducing lead times in the supply chain is a critical factor in improving supply chain efficiency, and the place to start is in optimizing your production processes. Doing so can help reduce the time it takes to manufacture products in the first place. Production processes can be optimized by implementing lean manufacturing principles, reducing setup times, and improving the flow of materials and information.

Once your production processes have been reviewed, take a close look at your supplier relationships. Creating strong relationships can make or break your supply chain. Strong communication and working closely with each supplier will help you increase trust, reduce problems, and negotiate better terms.

Finally, be sure to implement automation throughout the process. Automating supply chain processes, such as order processing, inventory management, and shipping, will help businesses reduce lead times and improve efficiency. This can be achieved by implementing software solutions that automate routine tasks and provide real-time visibility into supply chain operations.

2. Manage your inventory

Inventory management is often the bane of a logistics company’s existence. Fortunately, implementing regular due-diligence will make this process less painful. Inventory management often comes down to careful examination of both your manual and technological process.

Schedule regular inventory audits. It is very important that you schedule regular inventory audits at least twice a year, but these audits can be scheduled even more often if you are experiencing problems. Conducting regular inventory audits that include physical inventory counting, cycle counting, and more, will help your business identify discrepancies and ensure that inventory levels are accurate.

Examine your demand forecasting. Accurately forecasting demand is essential to effective inventory management. By analyzing historical sales data, market trends, and other relevant factors, you can forecast demand for your products and plan inventory levels accordingly. The right technology can help with this.

Consider using just-in-time (JIT) inventory management. JIT inventory management involves keeping minimal inventory on hand and relying on frequent deliveries from suppliers to maintain inventory levels. It has become popular in recent years to minimize costs associated with having too much inventory at any given time. It can help your business reduce inventory carrying costs and optimize supply chain processes.

Automate your processes. Implementing automated inventory management systems can help your business reduce manual labor and errors and improve inventory accuracy. This can include barcode scanning, RFID tracking, and other automated inventory tracking technologies.

3. Improve transportation logistics

Transportation also plays a key role in the efficiency of your supply chain. You can implement several strategies to keep your transportation running smoothly:

- Improve warehouse layout and processes. Improving warehouse layout and processes by streamlining the flow of products through the warehouse will help improve your logistics operations. This can be achieved by implementing lean principles that optimize warehouse layout, inventory management, and order fulfillment processes.

- Optimize transportation routes. Optimizing transportation routes will help your business reduce transportation costs and improve delivery times. This can be achieved by analyzing shipping data to identify the most efficient routes and modes of transportation as well as optimizing loading and unloading procedures.

- Implement real-time tracking. Implementing real-time tracking provides real-time visibility into shipments. This can help your business identify and resolve transportation delays and improve customer communication.

4. Use multi-carrier shipping software

Multi-carrier shipping software provides your business with access to multiple carriers and shipping services, enabling you to select the most cost-effective and reliable carrier for each shipment. Often, these software solutions will include rate shopping functionality, which allows you to compare shipping rates from different carriers in real-time. This can help you optimize your shipping costs and select the most cost-effective shipping option for each shipment.

Multi-carrier shipping software can automate shipping processes such as label generation, tracking, and billing to help you reduce manual labor and errors and improve shipping accuracy and speed. It typically also provides real-time tracking information, enabling you to track shipments in real-time and improve logistics operations.

As you select a multi-carrier solution, be sure you also look at its integration with other supply chain systems. The right multi-carrier shipping software should be able to smoothly integrate with inventory management, order processing, and warehouse management systems. This will be critical for you to streamline your logistics processes and improve overall supply chain efficiency.

5. Plan ahead

Planning ahead is essential to optimizing your supply chain processes. Start by developing contingency plans. Doing so can help you prepare for unexpected events that could disrupt your supply chain operations. This could include developing backup suppliers, securing additional inventory, or developing alternative logistics routes.

A big part of your contingency plan will rely on using the right technology. Implementing technology solutions such as inventory management systems, transportation management systems, shipping optimization software, and supply chain analytics platforms, can help you optimize your supply chain processes by providing real-time visibility, data analytics, and automation capabilities.

The future of supply chain optimization lies in technology

Experts agree that technology is likely to play an increasingly important role in the future of supply chain optimization. By leveraging emerging technologies, you can improve real-time visibility, predict demand more accurately, automate routine tasks, improve supply chain transparency, and enhance collaboration between supply chain stakeholders.

To fully optimize your supply chain, consider checking out a technology like Minisoft. We are a leading multi-carrier shipping software that offers best-in-class software solutions for supply chain execution and warehouse automation.

If you’d like to learn more about how we can help you optimize your supply chain, we’d love to chat. Click here to request a demo.